The Butler MR-24 Roof System Explained: Benefits, Lifespan & Cost Savings

When it comes to protecting a commercial building, the roof is one of the most important investments you’ll make. The Butler MR-24® Roof System is one of the most proven and reliable standing seam metal roof systems available. For more than 50 years, it has been trusted on warehouses, factories, schools, and other facilities because of its strength, long life, and ability to reduce maintenance costs.

In this article, we’ll explain what the MR-24 roof system is, how it works, the benefits it delivers, and why it’s considered the gold standard in metal roofing.

What Is the Butler MR-24 Roof System?

The Butler MR-24 roof system is a standing seam metal roof built for strength and weather protection. Each roof panel locks together with a 360-degree double seam. This creates a continuous seal that keeps out water more effectively than many other roof types.

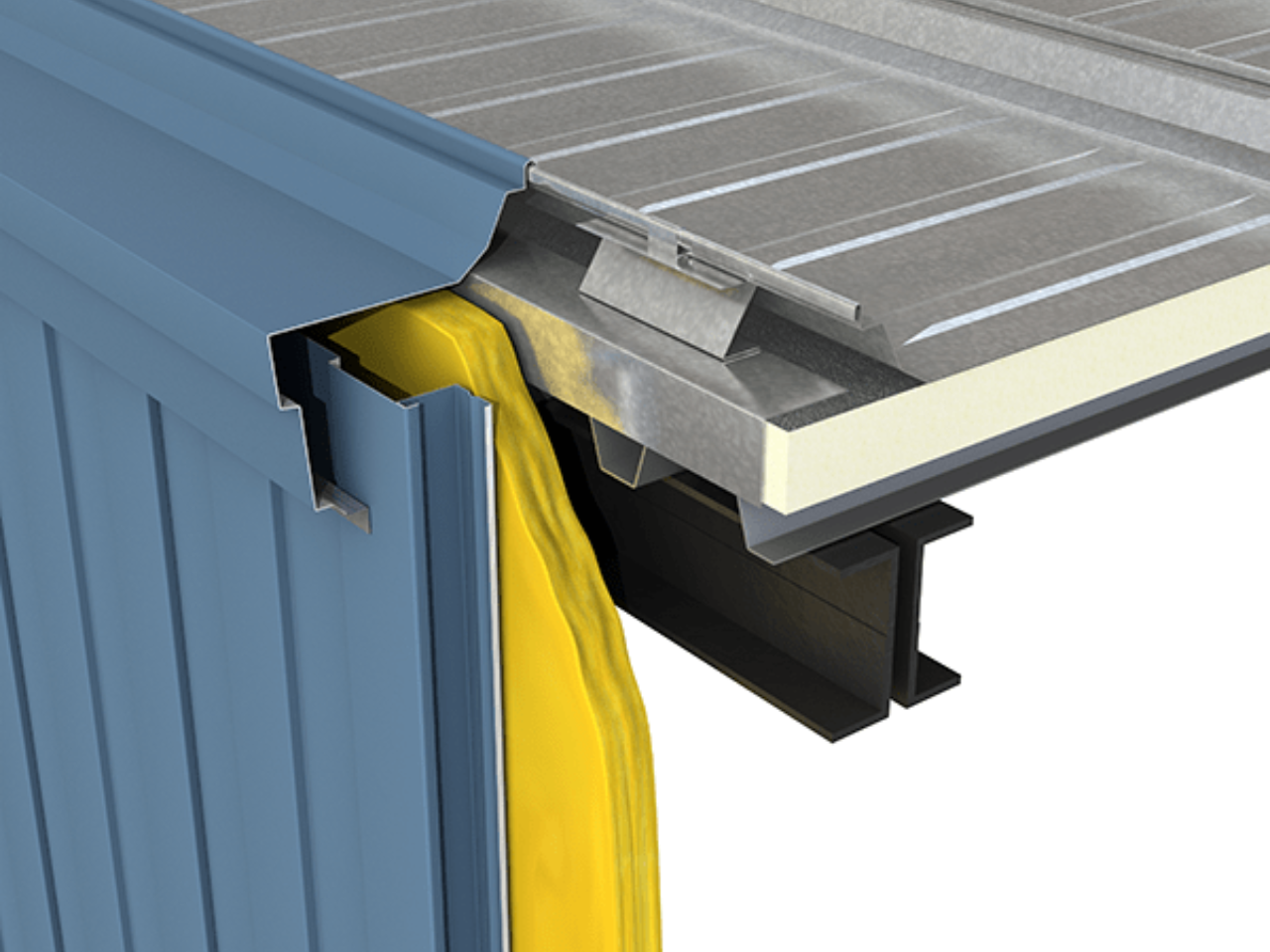

The Conventional Roof System version of the MR-24 is designed for steel-framed buildings with a metal deck. In this setup, the MR-24 panels are installed over:

A steel roof deck

Rigid insulation

A vapor barrier (to prevent condensation)

Bearing plates under the clips (to protect the insulation)

This design allows building owners to use MR-24 technology even if their project isn’t a pre-engineered metal building.

Key Features That Set the MR-24 Apart

360° Double-Lock Seam – The seam is locked twice during installation, making it almost impossible for water to get in.

Floating Clips – These clips allow the panels to expand and contract with temperature changes without putting stress on the seams.

Factory-Punched Panels – Panels are pre-punched for exact fit, which reduces errors and speeds up installation.

Proven Testing – The MR-24 meets strict ratings for wind, fire, and severe weather, including UL 580 Class 90 wind uplift and Miami-Dade County approval.

What Does an MR-24 Roof Cost? (and How It Saves Money Long-Term)

The cost of a Butler MR-24® roof depends on several project details. Choosing a heavier 22-gauge panel, for example, will increase strength but also raise the price compared to the standard 24-gauge option.

The type and thickness of insulation also affect cost, since additional layers improve energy efficiency but add material expense. Roof slope and overall design complexity play a role too—steeper pitches or unique layouts require more steel and labor.

Finally, penetrations such as skylights, HVAC units, and curbs increase installation time and detailing work, which can add to the overall cost.

Here’s how the MR-24 stacks up against other roofing options:

TPO/EPDM membranes – Lower upfront cost, but shorter lifespan (15–25 years). Most buildings will need two or more replacements during the lifespan of an MR-24 roof. Membranes are also prone to seam and puncture issues.

Through-fastened metal panels – Cheaper to install, but exposed screws loosen and leak over time, leading to higher repair costs. Lifespan is shorter than MR-24.

MR-24 standing seam – Lasts 50–60 years with very little maintenance. Studies show Galvalume steel can last three times longer than TPO. Butler reports MR-24 can cut maintenance costs by up to 90%.

When you consider fewer repairs, fewer replacements, and better energy savings, MR-24 often delivers the lowest overall cost over its life.

Roof System Lifespan Comparisons

When choosing a new roof, lifespan is one of the most important factors to consider. While membrane systems like TPO and EPDM may offer lower upfront costs, they usually need replacement within 15–25 years.

Through-fastened metal panels last a bit longer but require frequent repairs. In contrast, the Butler MR-24® roof system can deliver 50–60 years of performance with minimal maintenance, making it one of the longest-lasting commercial roofing options available.

Here’s a breakdown:

Roof Type | Typical Lifespan | Maintenance Needs | Common Issues |

Butler MR-24® (standing seam) | 50–60 years+ | Very low | Minimal — seams stay watertight, clips allow movement |

TPO Membrane | 15–25 years | Moderate | Seams separate, punctures, UV breakdown |

EPDM Membrane | 15–25 years | Moderate | Shrinkage, seam failure, punctures |

Through-Fastened Metal Panels | 20–30 years | Higher | Exposed fasteners loosen and leak over time |

Asphalt/Modified Bitumen | 15–20 years | Higher | Cracking, blistering, shorter life in harsh climates |

Butler MR-24 Roof System FAQs

How long does a Butler MR-24 roof last compared to TPO or EPDM?

Butler MR-24 roofs can last 50–60 years or more, while TPO and EPDM membranes typically last only 15–25 years. This means most buildings with TPO or EPDM will need two or more replacements in the same time an MR-24 roof remains in service.

Is the Butler MR-24 roof worth the higher upfront cost?

Yes. While the upfront cost of MR-24 is higher than TPO or through-fastened panels, its long lifespan, lower maintenance, and energy efficiency make it one of the lowest life-cycle cost options on the market.

Can you install solar panels on a Butler MR-24 roof without causing leaks?

Yes. Solar panels, HVAC units, and other equipment can be added using seam-clamped attachments that don’t penetrate the roof panels. This keeps the MR-24 system fully watertight and maintains warranty coverage.

What makes the Butler MR-24 roof system different from other standing seam metal roofs?

The MR-24 uses a 360-degree Pittsburgh double-lock seam, factory-punched panels for exact fit, and floating clips that allow panels to expand and contract. These features make it more weathertight, durable, and low-maintenance than most other standing seam roofs.

Does the Butler MR-24 roof system stand up to hail and severe storms?

Yes. The MR-24 roof has a UL 580 Class 90 wind uplift rating and Miami-Dade County approval for severe weather. Its heavy-gauge steel panels are also highly resistant to hail dents and punctures, making it one of the most storm-resilient roof systems available.

Final Thoughts: Is MR-24 Right for Your Building?

The Butler MR-24 roof system is one of the most durable and cost-effective commercial roofing solutions available today. Its seam design, storm ratings, and low maintenance needs make it a long-term investment that outperforms many other roofing types.

If you’re planning a new roof or replacement project, working with a certified Butler Builder ensures proper design and installation. Seufert Construction proudly serves as Southern Indiana’s Butler Builder, bringing more than 150 years of construction experience to businesses across Ferdinand, Evansville, Louisville, and more.